UFH Insulation: What are your options?

Are you ever confused by the massive range of UFH insulation products? We thought it would be useful to briefly summarise the main types of insulation that are used in conjunction with Underfloor Heating.

Board Insulation is by far the most common and popular insulation type, and it comes in a few different forms:

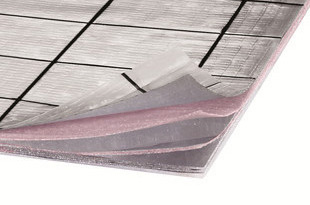

EPS, or Expanded Polystyrene Insulation, is a cost-effective and popular underfloor heating insulation and is the material used within our ‘Tacker’ sheet for our AmbiTak system. Typically having the appearance of a white plastic foam, EPS is manufactured by expanding a polystyrene polymer. A mould is used to contain small foam beads which heat or steam is then applied to and this causes the beads to expand and fuse together. This process forms a closed cell insulation.

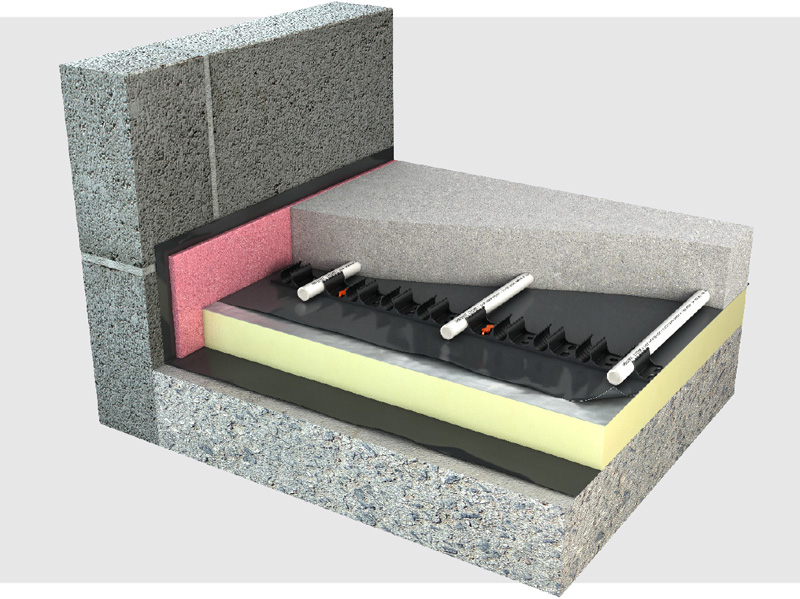

XPS, or Extruded Polystyrene, typically has a better insulation performance than EPS and is more durable. As the name suggests it is manufactured via an extrusion process, which involves melting polystyrene polymer together with other ingredients, the liquid formed is then continuously extruded through a dye and expands during the cooling process. XPS is a closed cell rigid foam insulation, and is often produced with a coloured dye such as yellow or red. Due to a more complex manufacturing process, it is more expensive than EPS.

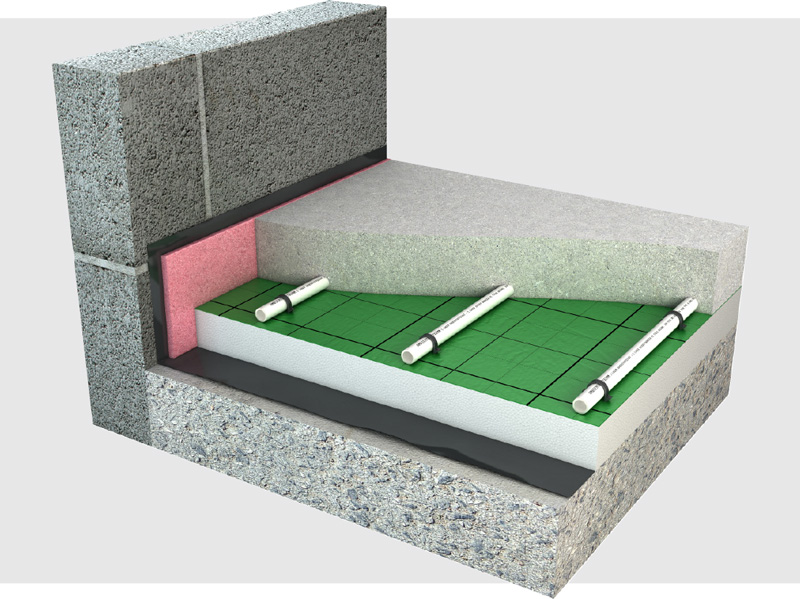

Rigid PUR and PIR boards are commonly used in ground floor applications, as part of a new-build screed floor build-up and can be used under our screeded systems. Rigid Polyurethane (PUR) and polyisocyanurate (PIR) products are highly effective, lightweight and have the ability to bond to most materials. Both have excellent thermal conductivity, have a high strength to weight ratio and due to versatility in the manufacturing processes there are a range of boards to choose from. As a result of this, they’re hugely popular for construction insulation applications.

Board insulation may however pose challenges in certain situations, due to its size and flexibility. Some other insulation types include:

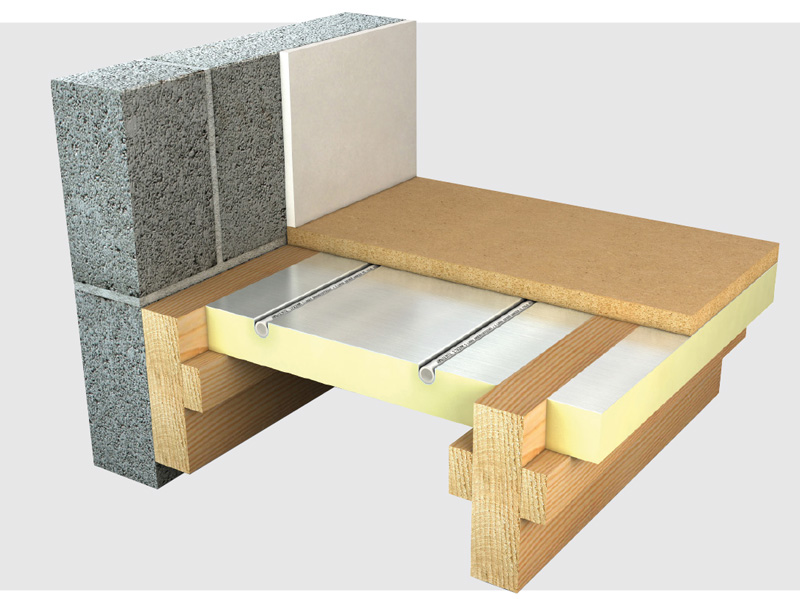

Mineral Wool is normally used for insulating joist voids due to its flexibility and works well with our AmbiPlate range of systems. Also known as mineral fibre and ‘Rockwool’ (a leading brand), this form of insulation is created by spinning or drawing molten or synthetic materials. The material is porous and traps the air, making it a fantastic thermal insulator and it often has acoustic abilities too. This insulation is also incombustible and doesn’t fuel or propagate flames.

Foil insulation can be used when height restriction is an issue. There are various multi-foil insulations which vary between 5-10mm and have an excellent performance given the minimal height build-up. This product consists of a series of layers of foil and plastic which gives a surprisingly high insulation value. Some manufacturers report that the insulation value is close to up to 40mm of EPS board insulation, while being a fraction of the size – this is ideal in refurbishment projects where floor build-up height must be kept to a minimum.

Further questions regarding which insulation to use with Underfloor Heating? Call one of the team today on 01707 649118

Did you find this article useful? Check out these posts on which is the best underfloor heating for joisted floors and which is the best underfloor heating system for screeded floors.